SPECIALISED PRINTING SERVICES

Create curiosity & maximise impact with innovative designs, from luxurious quality to unusual & quirky materials, utilising specialist printing techniques and finishes.

Paper, Card, Leather, Plastic, Wood, Metal, Glass & Fabrics

INCA’s 20 year reputation for excellence has been earned from consistently delivering quality resultsarise from fusing our meticulous attention to detail and sophisticated bespoke designs with high quality results, no matter how simple or complex your job.

Our friendly and experienced team, will guide you from understanding your initial brief to mock ups to the finished job, all to help create maximum impact for your budget and delivery schedule. When great design and superb printing come together, the results can be fantastic!

We work very closely with our clients from the early stages of a project to really define their vision and goals. We can utilise either our in-house designers or commission freelance design, as well as calling upon trusted artists, calligraphers or packaging engineers, all working together towards one common goal, a very happy client and project success.

Printing

When having most bespoke printing processes in-house, it gives us the ability to use these individually or as a combination to produce the best possible results to suit the design and brief. Not only this, but we also provide a wide range of machine finishing and hand assembly processes too, this enables us to have total control over all areas of production and quality. For more complex projects this is especially crucial to make sure all elements are working together seamlessly, to the right quality and delivery schedule.

Quality

Our extensive experience in the luxury printing sector has raised our own exacting standards and attention to detail. We are determined to surpass the standards of our clients, to honour and be worthy of their brand standards. We believe that when something has been made with care and attention to detail, then it will give the user a wonderful experience with an emotional connection to the piece, which is the ultimate aim for luxury personalised packaging, stationery and invitations.

Service

We pride ourselves on our customer service and believe that we should demand and surpass our client’s expectations for service as the norm. We make our client’s challenges our challenges and see every project through so a successful result is achieved for all involved.

SPECIALISED PRINTING SERVICES

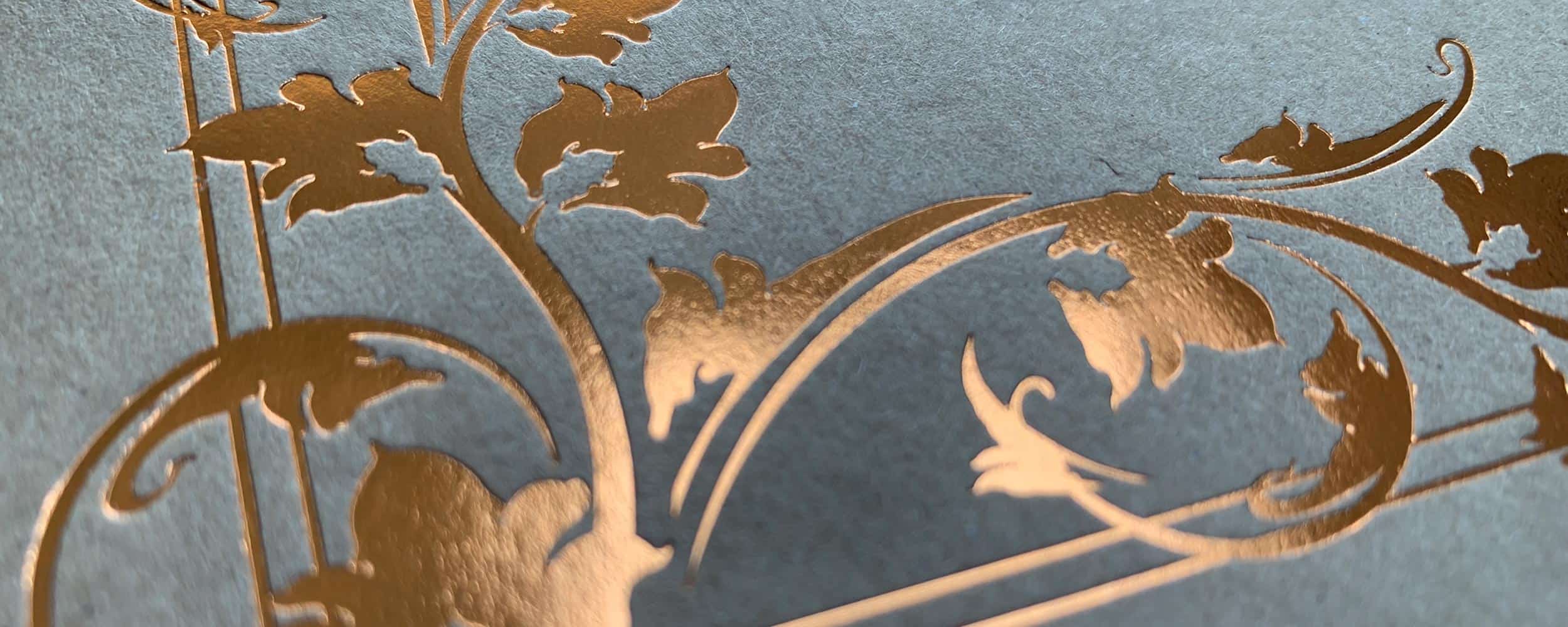

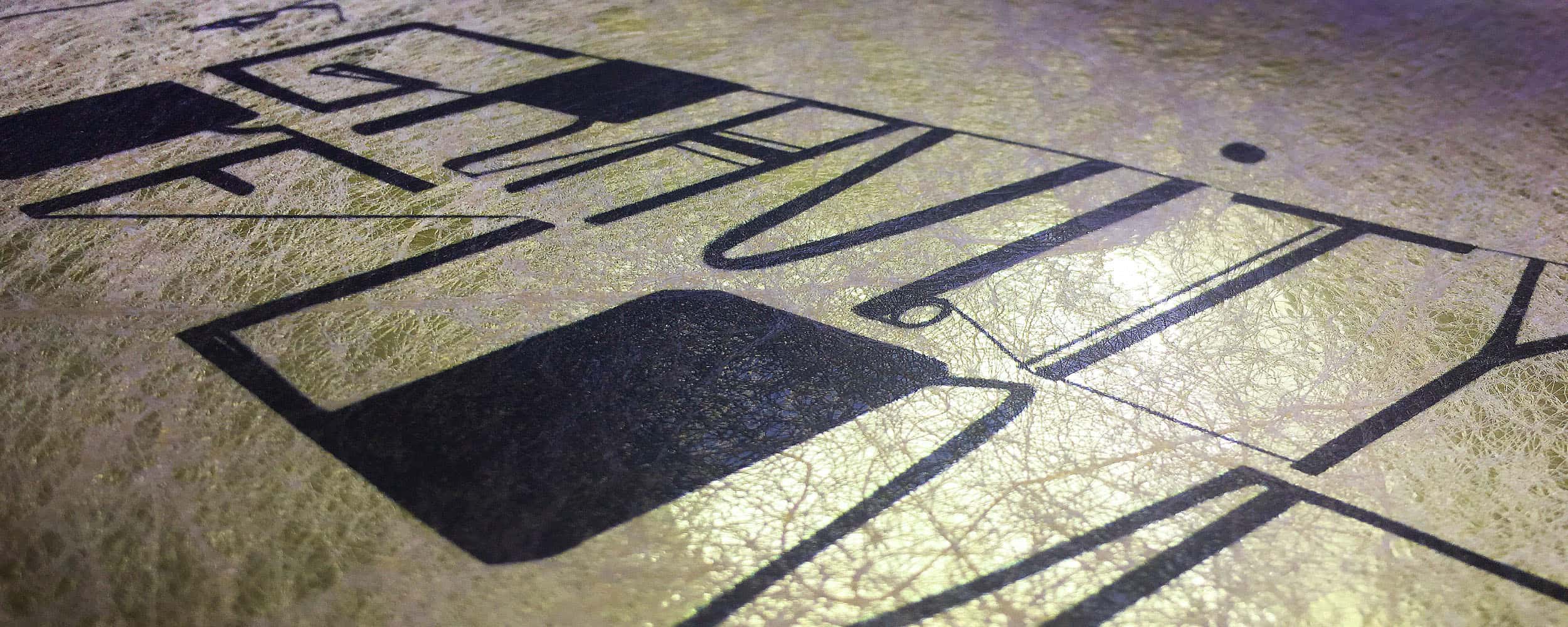

FOIL BLOCKING

To get the gold or silver stamp, a foil layer is affixed to the material by a heat transfer process. The hot foil stamping produces stunning results, especially when metallic or unusual foils are pressed into card stock to create a striking look with a gentle impression.

Thermography

Thermography produces raised printing for an elegant effect. In thermography, resin powder is applied to wet ink and then heat fused to create raised text that has a slight sheen.

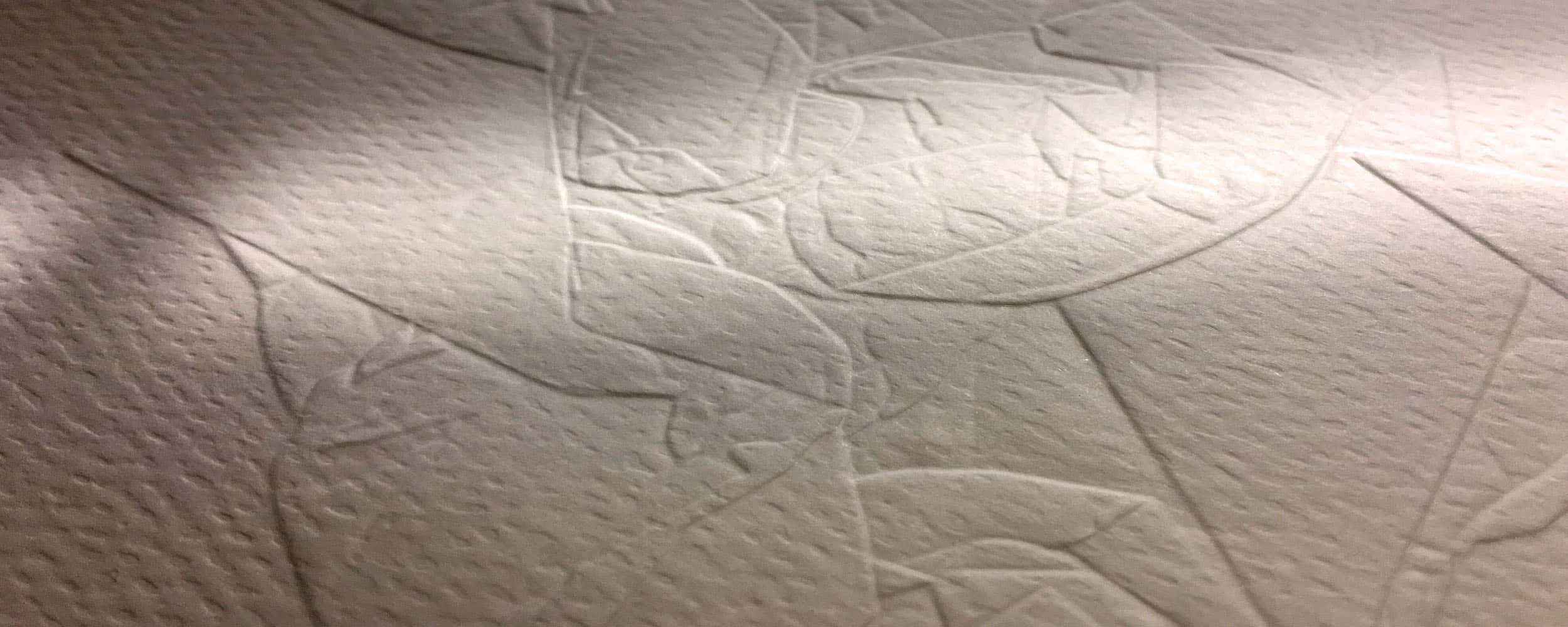

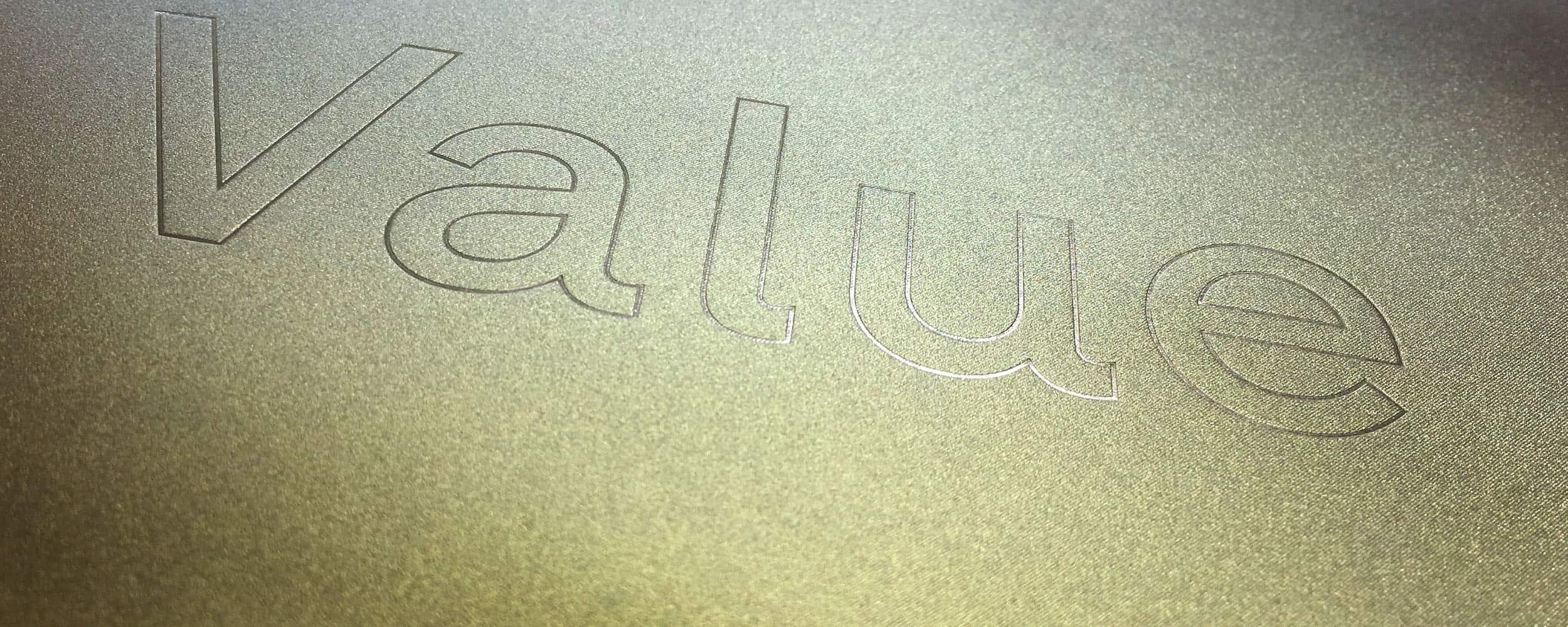

EMBOSSING & DEBOSSING

These similar processes can create very different results. Essentially, both processes involve making a metal plate and a counter; the plate is mounted on a press and the paper is stamped between the plate and counter. This force of pressure pushes the stock into the plate, creating the impression. Embossing produces a raised impression on your paper stock, while debossing creates a depressed impression.

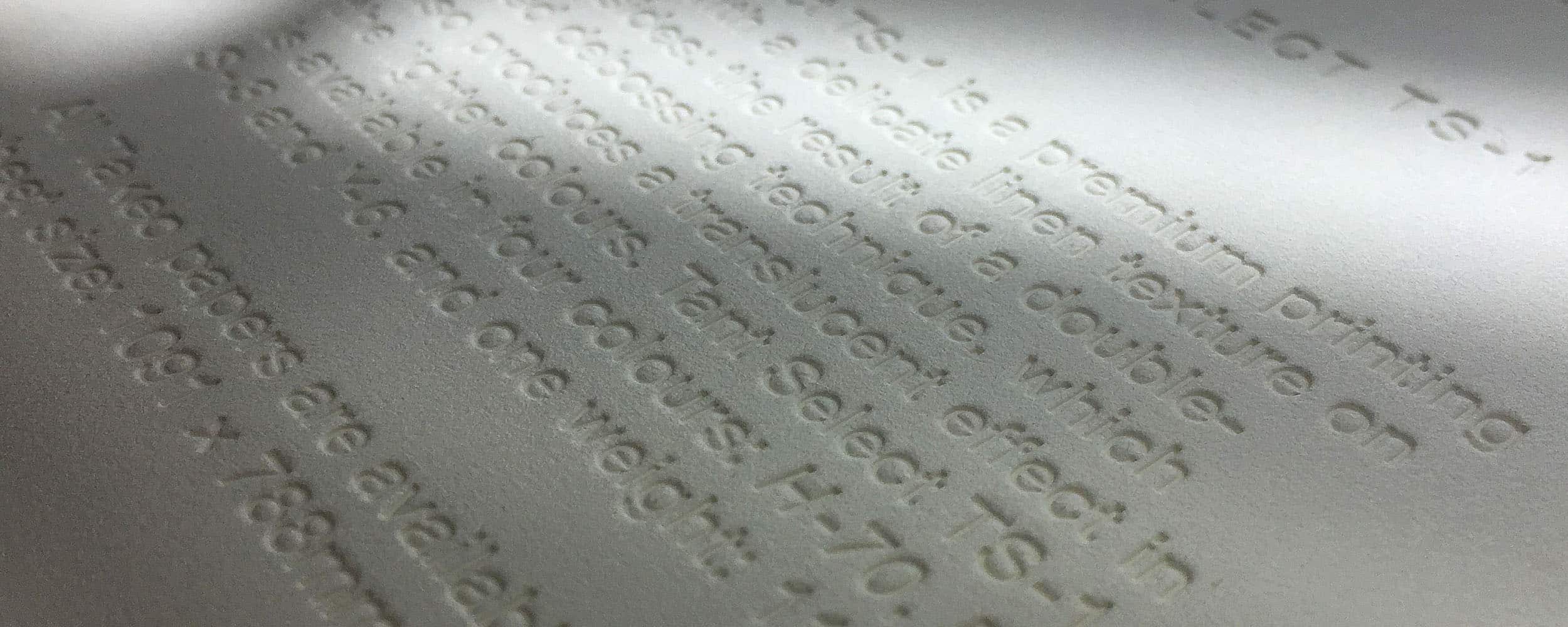

BLIND Embossing & Debossing

Simply by creating a three dimensional impression on the sheet with the use of a die and the absence of ink, blind embossing creates a visual and tactile appearance that is particularly effective with bold outlined artwork. A de-bossing effect can also be achieved.

PLATE SINKING

Plate Sinking is an embossing or debossing technique in which an area of the card is either ‘raised’ or ‘sunk’ in so that it sits higher or lower than the rest of the card creating a frame within the design.

COATINGS

Lamination Techniques

Lamination can be a liquid that dries to a tough gloss or dull surface, or it can be a film. Both adhere to the surface to protect it and give it either a soft sheen or a muted matt effect Therefore the resulting effect could be glossy, dull, or even satin.

Silk Lamination

Silk lamination provides a soft, silk-like finish, is water-resistant and tear-resistant, and complements vibrant colours. Designs traditionally printed in full-colour with an additional step taken to get a unique textured coating with a durable, weather-resistant, silk laminate finish; adding a clear glossy, matte, satin, or neutral finish.

Varnish

A varnish is a liquid coating applied to a printed surface to add either a clear glossy, matt, satin, or neutral finish:

Gloss Varnishing A gloss varnish gives the printed surface a glossy, sheen look.

Matte Varnishing A matte varnish gives the printed surface a non-glossy, smooth look.

Silk or Satin Varnishing A satin varnish gives the printed surface a neither a high gloss or matte, but the middle ground.

UV Varnishing Ultraviolet (UV) varnishing is a process for achieving an even more striking type of coating on your printed material. Either an all over UV seal applied all over the printed surface for a full effect or a spot varnish is applied to chosen areas of a printed piece. This has the effect of highlighting that part of the design or creating a 3D effect.

CUTTING

Die Cut

Die cut involves cutting irregular shapes in paper or paperboard using a die. A die can be used in printing for cutting. This technique can also be utilised for cutting to hold business cards or tickets or clever design can create innovate shapes or windows to embellish a piece. Also useful when scoring for a clean fold with thicker paper or card stock.

Dies are normally custom made. Some standard dies are available if you don’t need a custom template and may help reduce the cost of printing a special piece.

LASER CUTTING

Using a laser rather than a knife to cut the card gives a higher degree of precision therefore more detail can be achieved than using a more conventional die cutting process. Intricate and elaborate designs can really enhance a distinctive design.

LITHOGRAPHY

The traditional high quality offset process of flat printing works well in combination with most other printing processes. Pantone colours can be used for accurate spot colour matching. Process colours can be used for long full colour printing runs.

DIGITAL PRINTING

Vibrant and smooth to the touch, a flat printed and most versatile process for quick colour printing which is inexpensive and perfect for short runs.

LETTERPRESS

Centuries old, the letterpress process produces an imprinted or de-bossed impression on the card using a surface with raised letters that are inked and pressed to the surface of the printing substrate to reproduce an image in reverse.

Thick and soft cotton style papers and card highlight the letterpress technique.

Silk Screening

Silk Screening is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that allows ink to transfer onto the chosen material.

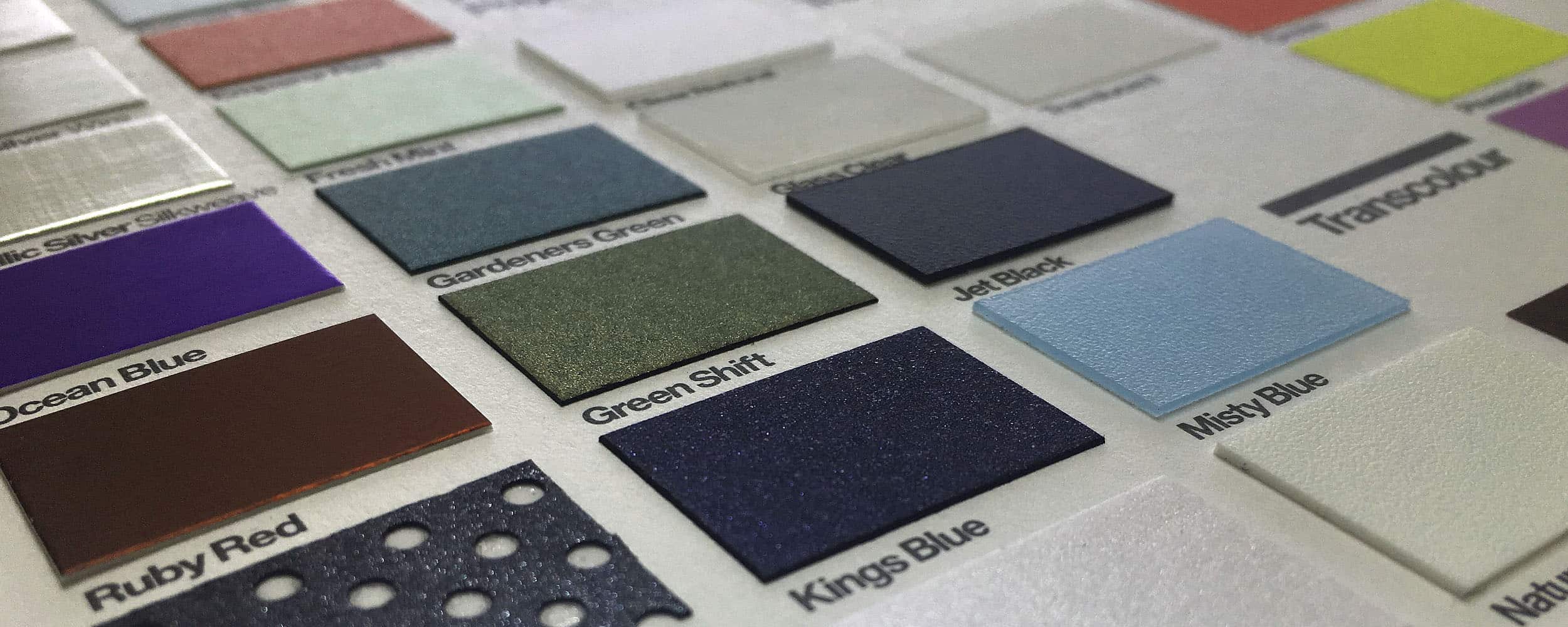

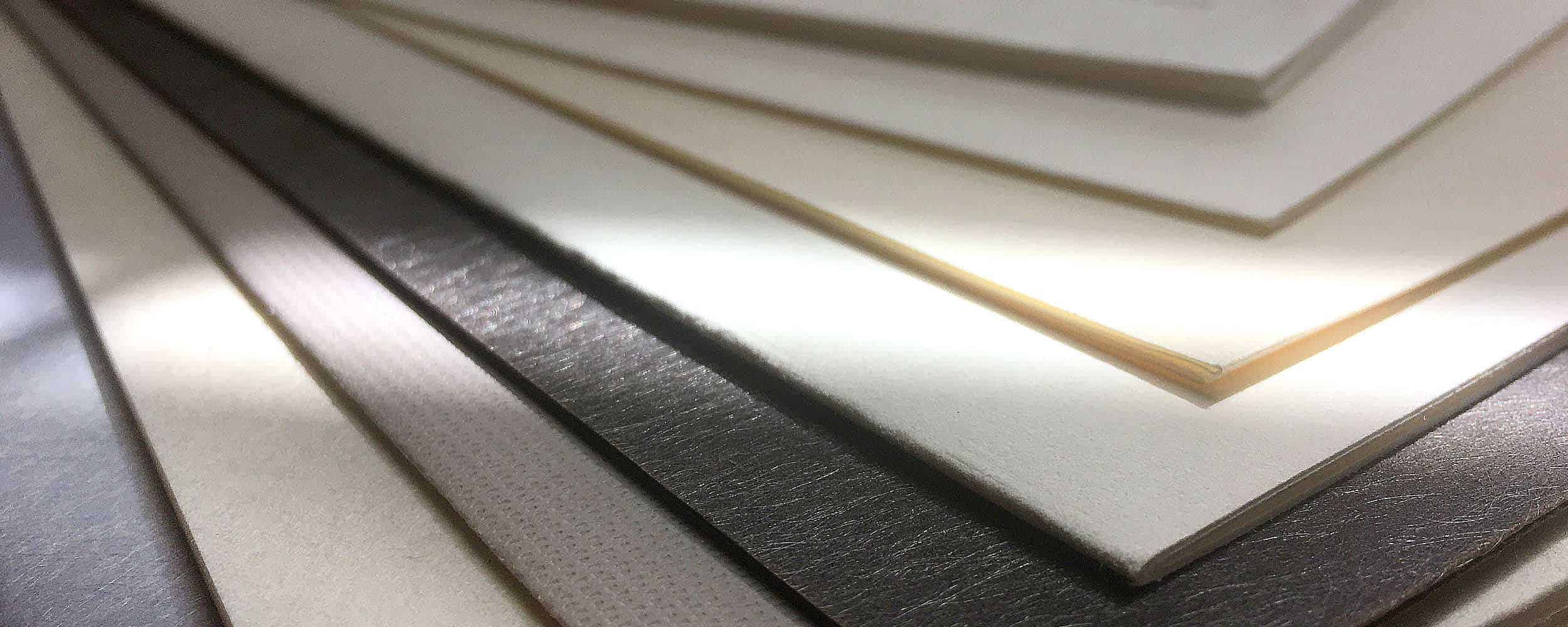

An unrivalled selection of paper & card;

Weights

Textures

Colours

DUPLEXING

Duplexing is when two or more sheets are bonded together. This process can be used to stick different materials/stocks/colours together to create card of any weight or even to cover up the impression on the reverse of a stamped card.

GILT & COLOURED EDGING

The specialised art of applying a gilt or coloured edge to a card, especially when bevelled, gives a perfect finishing touch to a prestigious design.

Hardback Casebooks

Visitor’s Guest Books

Photo Albums

Presentations

Bespoke Envelopes

Folders

Information Packs

Invitations

Announcements

Certificates

Menus & Place Cards

Labels & Stickers

Festive, Greetings & Thank You Cards

Notepads

Stationery

Letterheads

Newsletters

direct mailers

Reports

Leaflets & Flyers

Posters

Brochures

Sales Literature

Invoices

Documents

Calendars

Gift Vouchers

Packaging

Interior & Exterior Signage

Banners & Flags

Uniforms & garments

Vehicles